Navigating the Globe of Fasteners and Machining: Strategies for Accuracy and Rate

In the complex world of fasteners and machining, the pursuit for precision and rate is a perpetual difficulty that requires meticulous interest to information and tactical preparation. From comprehending the varied array of fastener types to picking optimal materials that can endure rigorous needs, each action in the procedure plays an essential function in attaining the preferred outcome. Precision machining methods better raise the intricacy of this craft, calling for a fragile balance in between technical knowledge and ingenious strategies. As we delve into the techniques that can improve both rate and performance in this domain name, the interaction in between quality control steps and functional quality becomes a crucial centerpiece.

Understanding Fastener Types

When picking bolts for a task, recognizing the numerous kinds offered is important for making sure ideal performance and integrity. Bolts are available in a variety of types, each made for certain applications and demands. Bolts are used with nuts to hold products together, while screws are versatile bolts that can be utilized with or without a nut, depending on the application. Nuts, on the various other hand, are internally threaded fasteners that friend with screws or screws, providing a secure hold. Washing machines are necessary for distributing the tons of the bolt and protecting against damage to the material being attached. Furthermore, rivets are permanent bolts that are suitable for applications where disassembly is not required. Recognizing the distinctions between these bolt kinds is vital for selecting the right one for the task, ensuring that the link is strong, durable, and trustworthy. By choosing the appropriate bolt kind, you can enhance the performance and long life of your task - Fasteners and Machining.

Choosing the Right Products

Understanding the value of picking the best materials is extremely important in ensuring the optimal performance and dependability of the picked bolt kinds talked about previously. When it pertains to fasteners and machining applications, the product option plays an essential function in establishing the total toughness, resilience, rust resistance, and compatibility with the designated atmosphere. Various materials offer varying properties that can considerably affect the efficiency of the bolts.

Common materials utilized for bolts consist of steel, stainless-steel, brass, titanium, and aluminum, each having its one-of-a-kind strengths and weak points. Steel is renowned for its high toughness and durability, making it suitable for a variety of applications. Stainless-steel offers outstanding deterioration resistance, suitable for settings prone to moisture and chemicals. Aluminum is lightweight and corrosion-resistant, making it ideal for applications where weight decrease is vital. Brass is commonly selected for its aesthetic appeal and superb conductivity. Titanium is understood for its outstanding strength-to-weight ratio, making it perfect for high-performance applications. Selecting the appropriate material involves taking into consideration aspects such as strength requirements, ecological conditions, and budget restraints to make check these guys out sure the desired efficiency and durability of the fasteners.

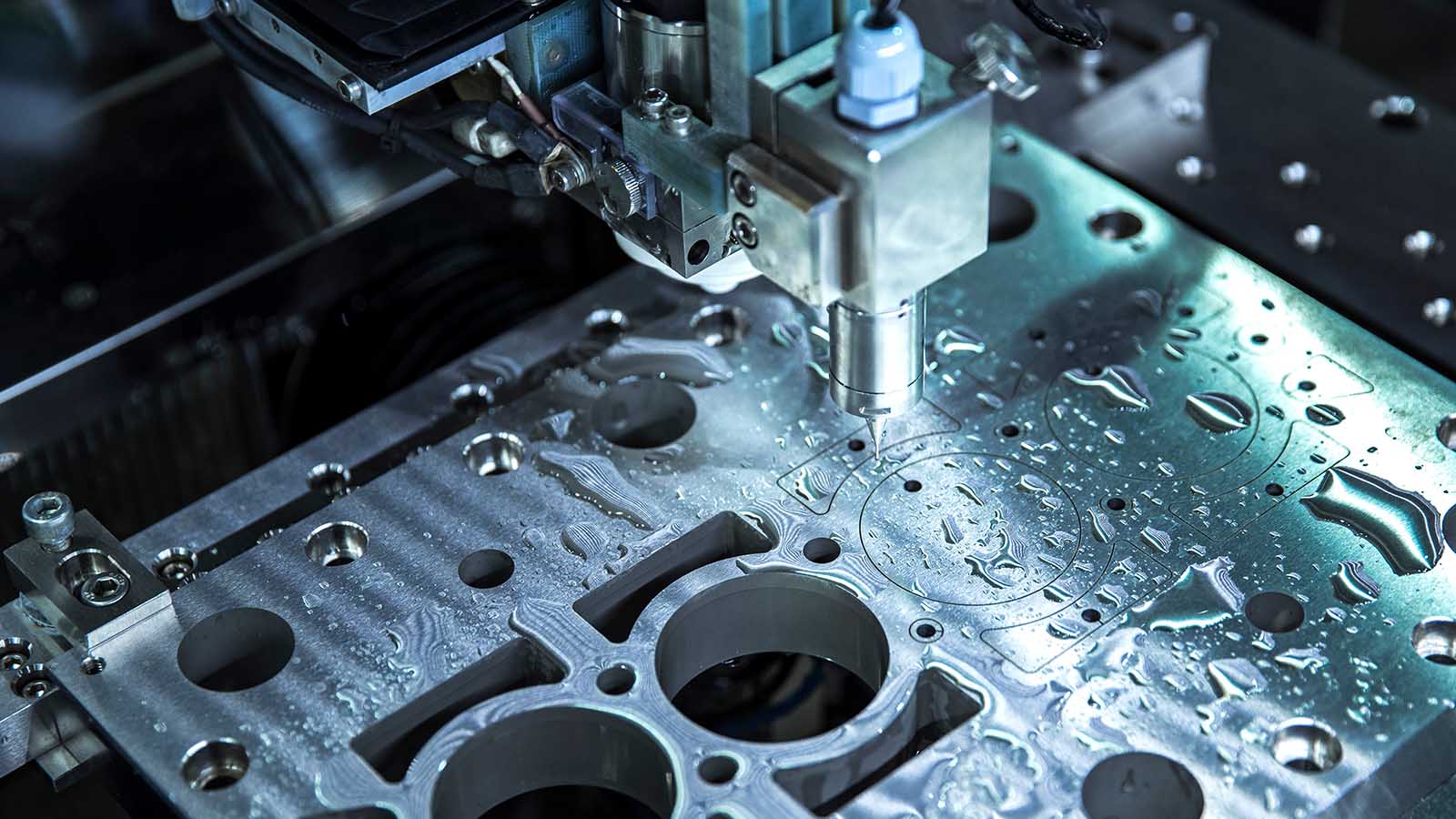

Accuracy Machining Techniques

Along with CNC machining, various other precision strategies like grinding, transforming, milling, and boring play vital duties in fastener manufacturing. Grinding assists accomplish fine surface area finishes and limited dimensional tolerances, while transforming is frequently made use of to create round parts with accurate sizes. Milling and exploration operations are crucial for shaping and developing holes in fasteners, guaranteeing they meet precise requirements and function properly.

Enhancing Rate and Performance

To enhance bolt production procedures, it is necessary to improve procedures and execute efficient methods that complement accuracy machining techniques. Automated systems can handle recurring jobs with precision and rate, enabling workers to concentrate on more facility and value-added activities. By incorporating these techniques, manufacturers can attain a balance in between speed and accuracy, ultimately boosting their affordable edge in the bolt market.

Quality Control Measures

Implementing strenuous top quality control actions is crucial in guaranteeing the reliability and consistency of fastener items in the production procedure. Fasteners and Machining. Quality control procedures include various phases, beginning from the choice my blog of raw products to the final examination of the completed fasteners. This includes analyzing factors such as material make-up, site stamina, and resilience to ensure that the fasteners satisfy sector requirements.

Regular calibration of devices and equipment is necessary to maintain uniformity in manufacturing and make sure that bolts meet the needed resistances. Carrying out stringent procedures for identifying and resolving non-conformities or flaws is essential in avoiding substandard items from getting in the market. By establishing a detailed quality assurance framework, makers can promote the credibility of their brand and provide bolts that fulfill the highest standards of performance and toughness.

Final Thought

In the intricate realm of bolts and machining, the pursuit for precision and speed is a perpetual difficulty that requires careful focus to detail and tactical preparation. When it comes to bolts and machining applications, the material selection plays an important role in figuring out the total toughness, resilience, rust resistance, and compatibility with the designated setting. Accuracy machining includes various advanced techniques that ensure the limited resistances and specs required for fasteners.In enhancement to CNC machining, various other accuracy methods like grinding, turning, milling, and drilling play vital duties in bolt production.To optimize bolt manufacturing procedures, it is vital to enhance operations and execute efficient approaches that enhance accuracy machining strategies.

Barry Watson Then & Now!

Barry Watson Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!